耐磨陶瓷材料企業

提供合理化防磨解決方案

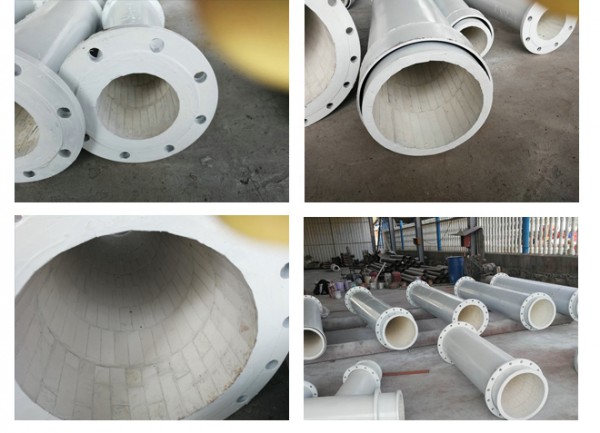

The wear-resistant ceramic pipe has good wear resistance: the ceramic layer of the wear-resistant ceramic elbow is made of wear-resistant engineering ceramics, and its hardness (HRA) is ≥90, and its wear resistance is more than 10 times that of high-chromium wear-resistant cast iron alloy pipe fittings. Using 5mm thick ceramic layer, its actual wear-resistant service life will be equivalent to 50mm thick wear-resistant cast steel.

Corrosion resistance of wear-resistant ceramic pipes: choose different wear-resistant ceramic materials, have excellent corrosion resistance to different corrosive media, acid, alkali, salt and other strong corrosive media and halogen salt corrosion characteristics.

The wear-resistant ceramic pipe has good high-temperature resistance: the wear-resistant ceramic itself has the ability to withstand high temperatures above 1200 degrees Celsius. Through reasonable design and the use of different composite methods, the wear-resistant ceramic pipe can be operated for a long time within the humidity range of -50 ℃ to 800 ℃. Especially suitable for high-temperature burner and other equipment lining. Lining engineering ceramics have high strength, high hardness, and excellent wear resistance and corrosion resistance; wear-resistant ceramic pipes reduce engineering cost: wear-resistant ceramic pipes are mainly used to convey liquid-solid two-phase flow substances and corrosive media with particles, used to replace prices Expensive stainless steel pipes, high-chromium cast steel pipes, and hard alloy wear-resistant pipes can directly reduce the engineering cost and extend the service life at the same time. The product has high cost performance, which can save the cost and time of maintenance and replacement of materials. Simple manufacturing process; light weight, convenient transportation and installation.